On the Ground With Toolmakers Helping Small Farmers Keep it Local

Local farmers need locally-made tools. Here are just a few of the tool providers making it happen.

On the Ground With Toolmakers Helping Small Farmers Keep it Local

Local farmers need locally-made tools. Here are just a few of the tool providers making it happen.

The Ronnie Baugh Tractors two-wheel and four-wheel tractors and the hand-push tool carrier on display in Paint Rock, ALby Ronnie Baugh Tractors

Since the back-to-the-land movement of the ’60s, many dedicated land workers have championed the hard work of DIY, highlighting self-sufficiency and personal growth, as well as an increased connection to the earth as hard-won sources of joy. Small farmers often tout the benefits of shopping locally, including improving food security and contributing to the local economy. Because of the stories and advocacy of dedicated land stewards who so keenly express the advantages of buying close to home, many folks have embraced local sources of food and other household goods. However, when it comes to buying tools to use on the farm, homesteaders and farmers often run to Tractor Supply or click “add to cart” on Amazon when they are in need of an implement to get the job done.

In part, this is due to the dearth of American-made tools. While John Deere and some other tractor brands are manufactured in the US, their tractors are notoriously expensive. And for many years, farmers were obligated to buy only licensed parts and use only certified repair shops to work on their equipment. For cash-strapped farmers, the inability to service their own equipment was often a crushing financial blow. Although there have recently been reforms to this policy because of “right-to repair” advocacy, many farmers are still distrustful of these large manufacturers. There are also precious few locally made options for hand tools that are more suited to a homestead or small human-scale farm.

If we want a future with more farmers, more fresh, healthy food and stronger local economies, we need infrastructure that supports small growers. Locally made tools, from hoes to tractors, are an important part of that support system and confer many of the same advantages as locally grown food. Meet three US-based toolmakers who want to change the landscape of tool buying and making to better support their local farmers and communities.

Conor Crickmore, Neversink Tools, Claryville, NY

Conor Crickmore is a farmer, first and foremost. At Neversink Farm, he works 1.3 acres of highly productive organic vegetables with help from a handful of part-time employees. Many folks know Crickmorefrom his popular series of farming instructional videos. These videos grew out of projects that were started for fun and, eventually, spurred on by positive feedback, grew into extensive informational courses. Crickmore described a similarly organic progression when establishing his tool business, which started in his garage. “On my farm, there were just certain tools we needed. We were not intending to start a business; we just wanted to cover the costs of making them,” he says. But demand for his tools was high and, six years later, Neversink tools employs seven people in a shop outfitted with specialized equipment such as composite molds and a metal-stamping setup.

Because Neversink Tools manufactures the tools it sells, it has e the flexibility to constantly tinker with design and update tools quickly. One of its most popular tools, the patented Mutineer hoe, features a system of interchangeable heads so farmers can choose the one best suited to cultivate in every condition. The lightweight heads can be carried on a carabiner, making it ideal for human-scale farms.

The Neversink team focuses on improving or upgrading existing tools or making specialized tools that fill a need on small intensive-production farms. “If we are going to make something that’s already out there, we are solving a problem. We don’t make something just because.”

All the work at Neversink Farm is guided by the ethos of constant improvement. There is a beautiful optimism in all of its content that tells farmers that they, too, can be successful and run a profitable business. “Farmers are creating incredible businesses and complicated infrastructures that support their hard work,” says Crickmore.

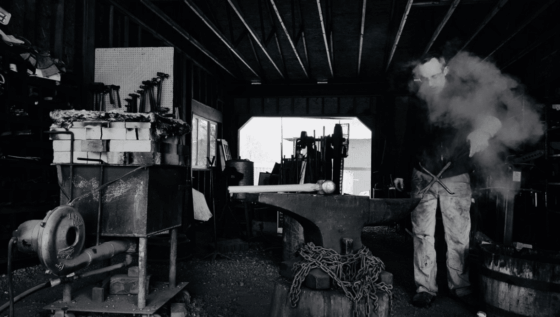

Seth Pauley, Red Pig Tools, West Linn, OR

Pauley is a blacksmith who forges his tools with an anvil and hammer, using equal parts artistry and strength. Pauley makes all the Red Pig products by hand with help from a couple of apprentices who are learning the art of smithing. Many of the designs are taken from old-world tools that are hundreds or thousands of years old, although Pauley also makes custom orders upon request.

Red Pig tools are designed to withstand the hard work of producing food. Handles for its hoes and other tools can be chosen to match the user’s height and can be easily replaced. Pauley hopes to disrupt the disposable consumer mindset and empower folks to service their own tools and take pride in artfully made objects, just as they take pride in their gardens. He recognizes that his tools are more expensive than the same item from a box store, but he says that, over time, the value is greater. “You can get a good tool that can last you a lifetime… You can sharpen it. You may even learn to use a welding rig… There’s a lot of things you can learn to do to make a good tool last.” To support folks along this journey, Pauley makes himself available for phone calls and shop visits and tirelessly educates folks at garden shows and other venues.

He emphasizes that well-designed, well-built hand tools can help reduce the barrier to entry for small farmers, for whom tractors and power equipment can be financially out of reach. “You don’t have to be limited by the cost of the equipment,” he says. “You don’t have to play the same game as the bigger farms.”

He, too, is optimistic about the future of sustainable farming. “I am seeing a lot of younger people who are more interested in growing things and doing something outside of a traditional 9-5 office job,” says Pauley. “There’s a lot of people who are interested in doing things or making things and that’s only gaining traction.”

Horace Green, Ronnie Baugh Tractors, Paint Rock, AL

At 89 years old, Horace Green sees his tool company as a part of a wider picture that can help bring back small, productive rural economies. Growing up in rural Alabama, Green remembers how the transition from mule to mechanization helped small farmers. But he also keenly recalls how the “go big or go home” era of ag policy decimated rural communities. He emphasizes finding the right tool for the right scale. Ronnie Baugh offers lightweight, tractors that can be customized by their width, height and center of gravity.

Even in the US, the price of a full-size tractor is still out of reach for many small-scale farmers. Smaller, two-wheel tractors as well as hand-push tool carriers are in development at the shop. A former software engineer, Green firmly believes in open-source design and is committed to the right to repair. The new products are made using common parts such as bicycle wheels, which will allow farmers to source, build and repair components themselves. These push-driven cultivators can be upgraded using a bicycle motor and the adjustable toolbar can be swapped over to a larger two-wheel tractor. While the barrier to entry is low, the company still prioritizes quality. “We build for the life of the farmer, not the life of the product,” says Green.

Follow us

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Want to republish a Modern Farmer story?

We are happy for Modern Farmer stories to be shared, and encourage you to republish our articles for your audience. When doing so, we ask that you follow these guidelines:

Please credit us and our writers

For the author byline, please use “Author Name, Modern Farmer.” At the top of our stories, if on the web, please include this text and link: “This story was originally published by Modern Farmer.”

Please make sure to include a link back to either our home page or the article URL.

At the bottom of the story, please include the following text:

“Modern Farmer is a nonprofit initiative dedicated to raising awareness and catalyzing action at the intersection of food, agriculture, and society. Read more at <link>Modern Farmer</link>.”

Use our widget

We’d like to be able to track our stories, so we ask that if you republish our content, you do so using our widget (located on the left hand side of the article). The HTML code has a built-in tracker that tells us the data and domain where the story was published, as well as view counts.

Check the image requirements

It’s your responsibility to confirm you're licensed to republish images in our articles. Some images, such as those from commercial providers, don't allow their images to be republished without permission or payment. Copyright terms are generally listed in the image caption and attribution. You are welcome to omit our images or substitute with your own. Charts and interactive graphics follow the same rules.

Don’t change too much. Or, ask us first.

Articles must be republished in their entirety. It’s okay to change references to time (“today” to “yesterday”) or location (“Iowa City, IA” to “here”). But please keep everything else the same.

If you feel strongly that a more material edit needs to be made, get in touch with us at [email protected]. We’re happy to discuss it with the original author, but we must have prior approval for changes before publication.

Special cases

Extracts. You may run the first few lines or paragraphs of the article and then say: “Read the full article at Modern Farmer” with a link back to the original article.

Quotes. You may quote authors provided you include a link back to the article URL.

Translations. These require writer approval. To inquire about translation of a Modern Farmer article, contact us at [email protected]

Signed consent / copyright release forms. These are not required, provided you are following these guidelines.

Print. Articles can be republished in print under these same rules, with the exception that you do not need to include the links.

Tag us

When sharing the story on social media, please tag us using the following: - Twitter (@ModFarm) - Facebook (@ModernFarmerMedia) - Instagram (@modfarm)

Use our content respectfully

Modern Farmer is a nonprofit and as such we share our content for free and in good faith in order to reach new audiences. Respectfully,

No selling ads against our stories. It’s okay to put our stories on pages with ads.

Don’t republish our material wholesale, or automatically; you need to select stories to be republished individually.

You have no rights to sell, license, syndicate, or otherwise represent yourself as the authorized owner of our material to any third parties. This means that you cannot actively publish or submit our work for syndication to third party platforms or apps like Apple News or Google News. We understand that publishers cannot fully control when certain third parties automatically summarize or crawl content from publishers’ own sites.

Keep in touch

We want to hear from you if you love Modern Farmer content, have a collaboration idea, or anything else to share. As a nonprofit outlet, we work in service of our community and are always open to comments, feedback, and ideas. Contact us at [email protected].by Melissa Julia, Modern Farmer

May 13, 2024

Modern Farmer Weekly

Solutions Hub

Innovations, ideas and inspiration. Actionable solutions for a resilient food system.

ExploreExplore other topics

Share With Us

We want to hear from Modern Farmer readers who have thoughtful commentary, actionable solutions, or helpful ideas to share.

SubmitNecessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and are used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies.