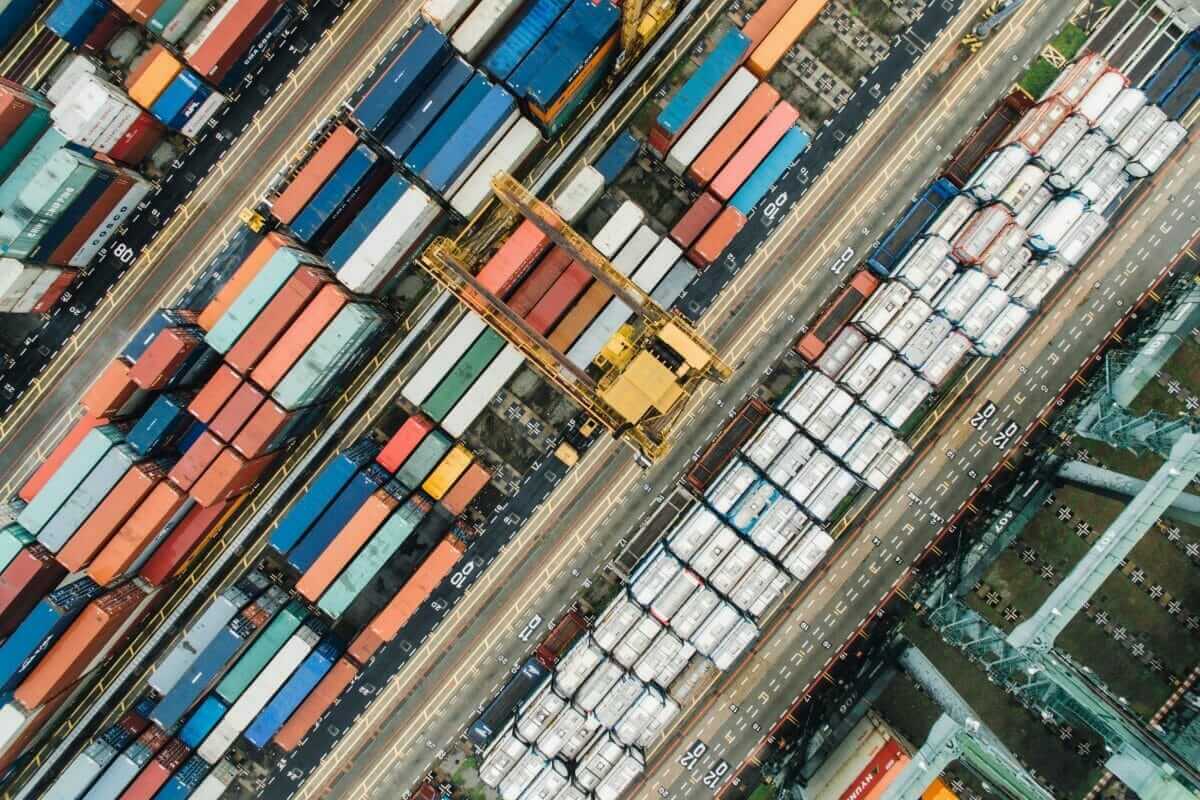

Mystic Cheese: Modular shipping containers are being repurposed for food production.

The so-called “cheese pods” that have helped the Mystic Cheese Co. grow are actually upcycled containers, now being used by food producers across the country.

Mystic Cheese: Modular shipping containers are being repurposed for food production.

The so-called “cheese pods” that have helped the Mystic Cheese Co. grow are actually upcycled containers, now being used by food producers across the country.

chuttersnap / Unsplash

On a 900-acre family-run dairy farm in Lebanon, Connecticut, two shipping containers sit among the barns and fields. Inside, in what is probably one of the smallest cheese-production facilities in the country, Brian Civitello creates cheeses that are winning the hearts of professional and home chefs alike.

Soft-ripened and buttery, with a mildly sweet yet tart taste, Mystic Cheese Co.’s signature product, Melville cheese, is a kitchen workhorse. Great in pastas, grilled cheese sandwiches and any dish that calls for melty cheese, it can be found in restaurants and specialty markets throughout the United States. But this cheese, along with four other types that the company now produces, wouldn’t exist without the upcycled shipping containers that Civitello fondly refers to as “cheese pods.”

“We never would have been able to grow without the pods,” says Civitello. “They allowed us to test the waters and focus on developing the brand.”

Across the country, people now use upcycled shipping containers to grow mushrooms and herbs and even serve as restaurants. But when Civitello and his business partner, Jason Sobocinski, began Mystic Cheese Co., in 2013, their use in food production was relatively new. “We were just throwing spaghetti against the wall,” says Civitello.

The containers let them keep costs and production time low. By taking milk directly from cows on the farm for cheese production, they have been able to age 30,000 pounds of cheese a year on average. The process blends Civitello’s love of technology with lessons learned from a childhood growing up on a small family farm. After spending his early 20s as a DJ, Civitello was inspired by his Italian grandfather to study cheesemaking in Italy. He learned how to make cheese over an open fire in a copper pot from a cheesemaker in the Alps and studied industrial production from some of the larger cheesemakers.

“I like technology, and I don’t mind industrial production,” says Civitello. “I thought if this guy is in the mountains, doing it by hand, how are these guys making it? What I learned is that there are parts they keep their hands on and parts that can be done by more efficient systems. Cheesemaking is a mix of science and art.“

Yet, when Civitello returned from Italy, producing cheese was an afterthought. He started a consulting business for cheesemakers but grew tired of doing what was essentially damage control on mistakes made during the construction of production facilities. Wanting to make a mobile infrastructure he could build and send to cheesemakers, he created the pods that became Mystic Cheese Co. “Mystic Cheese Co. took off so fast that we disbanded the consulting business,” says Civitello.

This fall, the company will more than double their production capacity by moving into a 4,000-square-foot facility. There, they’ll not only ripen cheese but also open a full-service cheese shop and café that will connect to a brewery in the same building. Not bad for a company that started out of two eight-by-40-foot containers.

From Mushrooms to Meat Processing

Over the past few years, the use of upcycled shipping containers in the food industry has exploded. Here are just a few of the ways they are being used.

A mushroom nursery

In shipping containers in Brooklyn, Smallhold has a mushroom nursery that grows the vegetables until they’re ready to be put into miniature farms at restaurants throughout New York City.

A solution to filling the food gap

To create a year-round food supply, the Community Food Bank of Eastern Oklahoma installed a vertical farm in two eight-by-40-foot shipping containers that can produce up to 1,800 heads of lettuce and other leafy greens every 45 days.

A meat processing plant

Plant In A Box and Dirigo Food Safety created United States Department of Agriculture–compliant slaughter and processing plants in eight-by-40-foot shipping containers.

A farm

One of the most popular uses for shipping containers is mini-farms. Los Angeles-based Local Roots Farms buys shipping containers from the Port of Los Angeles and renovates them into mini-farms, which have sold produce to organizations like SpaceX and the United Nations. New York-based Square Roots uses shipping containers to grow leafy greens year-round.

A restaurant

A number of restaurants, including the Miami-based Charcoal, call shipping containers home.

Follow us

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Want to republish a Modern Farmer story?

We are happy for Modern Farmer stories to be shared, and encourage you to republish our articles for your audience. When doing so, we ask that you follow these guidelines:

Please credit us and our writers

For the author byline, please use “Author Name, Modern Farmer.” At the top of our stories, if on the web, please include this text and link: “This story was originally published by Modern Farmer.”

Please make sure to include a link back to either our home page or the article URL.

At the bottom of the story, please include the following text:

“Modern Farmer is a nonprofit initiative dedicated to raising awareness and catalyzing action at the intersection of food, agriculture, and society. Read more at <link>Modern Farmer</link>.”

Use our widget

We’d like to be able to track our stories, so we ask that if you republish our content, you do so using our widget (located on the left hand side of the article). The HTML code has a built-in tracker that tells us the data and domain where the story was published, as well as view counts.

Check the image requirements

It’s your responsibility to confirm you're licensed to republish images in our articles. Some images, such as those from commercial providers, don't allow their images to be republished without permission or payment. Copyright terms are generally listed in the image caption and attribution. You are welcome to omit our images or substitute with your own. Charts and interactive graphics follow the same rules.

Don’t change too much. Or, ask us first.

Articles must be republished in their entirety. It’s okay to change references to time (“today” to “yesterday”) or location (“Iowa City, IA” to “here”). But please keep everything else the same.

If you feel strongly that a more material edit needs to be made, get in touch with us at [email protected]. We’re happy to discuss it with the original author, but we must have prior approval for changes before publication.

Special cases

Extracts. You may run the first few lines or paragraphs of the article and then say: “Read the full article at Modern Farmer” with a link back to the original article.

Quotes. You may quote authors provided you include a link back to the article URL.

Translations. These require writer approval. To inquire about translation of a Modern Farmer article, contact us at [email protected]

Signed consent / copyright release forms. These are not required, provided you are following these guidelines.

Print. Articles can be republished in print under these same rules, with the exception that you do not need to include the links.

Tag us

When sharing the story on social media, please tag us using the following: - Twitter (@ModFarm) - Facebook (@ModernFarmerMedia) - Instagram (@modfarm)

Use our content respectfully

Modern Farmer is a nonprofit and as such we share our content for free and in good faith in order to reach new audiences. Respectfully,

No selling ads against our stories. It’s okay to put our stories on pages with ads.

Don’t republish our material wholesale, or automatically; you need to select stories to be republished individually.

You have no rights to sell, license, syndicate, or otherwise represent yourself as the authorized owner of our material to any third parties. This means that you cannot actively publish or submit our work for syndication to third party platforms or apps like Apple News or Google News. We understand that publishers cannot fully control when certain third parties automatically summarize or crawl content from publishers’ own sites.

Keep in touch

We want to hear from you if you love Modern Farmer content, have a collaboration idea, or anything else to share. As a nonprofit outlet, we work in service of our community and are always open to comments, feedback, and ideas. Contact us at [email protected].by Bridget Shirvell, Modern Farmer

October 23, 2018

Modern Farmer Weekly

Solutions Hub

Innovations, ideas and inspiration. Actionable solutions for a resilient food system.

ExploreExplore other topics

Share With Us

We want to hear from Modern Farmer readers who have thoughtful commentary, actionable solutions, or helpful ideas to share.

SubmitNecessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and are used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies.