The Cheesemaking Monk of Manitoba

Six elderly monks keep a recipe for a delicious handmade cheese — one that may soon disappear.

The Cheesemaking Monk of Manitoba

Six elderly monks keep a recipe for a delicious handmade cheese — one that may soon disappear.

Holland is in southwestern Manitoba, about 50 miles from the North Dakota border. Passing it on the highway, as most do, it appears as little more than a grain elevator, a decorative windmill and a mural dedicated to a local champion high jumper.

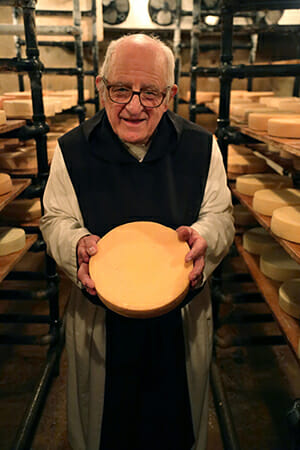

South of town, where the number 34 highway reaches the crest of a hill, you can see the bells of the monastery of Notre Dame Des Prairies (Our Lady of the Prairies). Once a sizable monastery, just six elderly monks live here today – keepers of a recipe for a handmade cheese that may soon be lost to history.

Cistercian — or Trappist — monks are vigorously self-sufficient. To earn an income, many make products like craft beer, wine, chocolate and other handmade goods. The monks of New Melleray Abbey in Iowa, for instance, make caskets.

At Notre Dame Des Prairies, they make cheese. Their Fromage de La Trappe is a pale orange, nutty, slightly salty, washed-rind cheese that’s sold in just a few stores and restaurants in Manitoba.

It’s mid-November and just one degree Fahrenheit, the first cold snap of the winter. But inside the cheese factory, it’s muggy and smells like warm milk.

At 80, Brother Alberic is the monastery’s sole full-time cheesemaker. He’s bent with age, but moves purposefully. His English is excellent, though built on a solid foundation of Quebecois French. If you were to squint, you might notice a passing resemblance to Robert De Niro, in a hairnet and rubber boots.

His “factory” has the look of a small restaurant kitchen, with plastic buckets full of utensils and milk cans scattered around the floor, and a little statue of Mary peering down from a set of cabinets.

He’s keeping a close eye on a slowly warming vat of raw milk and rennet. When it’s ready, he gets up and dips a pinky finger in the vat to test the thickness, then starts cutting the curds with a tool that looks like an elongated, stainless steel fly swatter.

He stirs as they separate from the whey, then using a conical sieve, scoops the dripping curds from the vat, plops them into moulds to shape and then over to a set of presses to drain. This evening he’ll return to put weights on the presses, where they’ll sit overnight.

“There,” he says. “Now you know how to make the cheese.”

Of course, that’s only the beginning – tomorrow his cheese will be taken to the cellars to ripen.

Ripening is the part of cheese making that seems especially suited to the pace of life in the monastery. The balance of temperature and humidity in the cellars must be carefully monitored, and each wheel of cheese must be carefully washed once a day.

There are hundreds of wheels in Alberic’s cellar — from plump, pale newcomers to taut, pungent wheels, aged the two months legally required for sale. Each afternoon, Alberic paces the cellar, hauling a plastic bucket of brine. He washes and flips each wheel individually, his heavy breath echoing off the concrete walls.

Ripening is the part of cheese making that seems especially suited to the pace of life in the monastery.

“It’s monkey work,” he says. “You just wash the cheese, turn the cheese, wash the cheese. When you have four or five hundred to wash, you know, at the end your head turns with the cheese.”

In the cellar, the old, hunched, monk cuts a timeless figure. A similar process, after all, dates back centuries in Europe. But the story of Alberic’s cheese, as he tells it anyway, begins more recently: with a traveling monk named Brother Alphonse Juin.

In 1893, Brother Juin, of the Bellefontaine Abbey in France, brought the recipe for Port-du-Salut cheese to the monastery of Notre-Dame du Lac — also known as Oka Abbey — in Quebec. At Oka, Juin helped the monks develop a namesake cheese, which is still popular in Canada today.

According to Alberic, that same technique was originally bestowed on the monks of St. Norbert, Manitoba, as a Christmas gift in 1918. They produced the cheese until 1950; that year, their monastery and cheese factory were damaged when the Red River flooded its banks, ending their commercial cheese business for several decades. And like the river, the suburbs of Winnipeg soon arrived on the monks’ doorstep, causing the brothers to relocate in the 1970s to the more remote Holland, Manitoba.

Alberic has been a monk since he was sixteen years old. He began his monastic career at Oka, where he worked in the dairy, but claims his cheesemaking technique was passed to him by a church superior while he was living in Manitoba. “He says I want to talk to you, and he gave me an envelope. He says, keep this because you will need this later on,” says Alberic. “When I looked at it, it was the recipe of the cheese that we received in 1918 and all the letters, the exchange between the brothers of Quebec and the brothers of Manitoba.”

Alberic also claims to be in possession of a secret notebook, sent to him by the monks at Oka. He says it contains the observations of another cheesemaking monk named Brother Oswald, and with them, instructions to burn the notes if ever he left the business, or no longer found them useful.

That’s his story. But it’s a contested one. Agropur – a large Quebec-based dairy co-op – now own the rights to Oka cheese, one in a long list of brands within its fold. Unlike Alberic’s, their products are pasteurized, and though the Oka monks helped the company for many years, today no monk plays a hand the production of Oka cheese. Agropur denies Alberic’s claims that his cheese comes from an original recipe shared by Oka. Two separate company representatives have told me, with conviction, that the best proof of their product’s uniqueness is a taste test. That, I leave up to you.

And whether or not Alberic’s cheese descends from Brother Alphonse Juin’s may soon be of little consequence. That’s because, in all his years of making cheese, Alberic has not arranged for a successor. His current helper – 41-year-old Brian Hay – says he doesn’t know if the monastic life is for him. A previous assistant also showed promise, but like so many young men initially drawn to the Trappist life, he soon moved on as well.

“He left, and a few months after that, he was married,” says Alberic, pausing as a little smile creeps on the corners of his lips.”C’est la vie.”

At this point, Alberic is even considering teaching a non-monk how to make his cheese. He says he has some potential, if unlikely, prospects. But even with the future of his life’s work in question, he remains mostly nonplussed. Alberic, after all, is blessed with a believer’s outlook. If things don’t work out, this life is just an opening act anyway.

“If the Lord sends somebody, so be it,” he says. “If not, by the time I die, it will be the last of my problems.”

Alberic spends his afternoon at the cheese shop. It’s sparse, dimly lit, adorned with intense religious iconography – it has little curb appeal. And yet, several customers arrive nonetheless, from who knows where, to buy Alberic’s cheese at the sort of price only a holy man could justify. He’s open just three hours a day, then closes promptly for evening prayer.

He’ll be at it again the next day, and the day after that, for as long as he’s able.

All photos courtesy Max Leighton.

Follow us

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

Want to republish a Modern Farmer story?

We are happy for Modern Farmer stories to be shared, and encourage you to republish our articles for your audience. When doing so, we ask that you follow these guidelines:

Please credit us and our writers

For the author byline, please use “Author Name, Modern Farmer.” At the top of our stories, if on the web, please include this text and link: “This story was originally published by Modern Farmer.”

Please make sure to include a link back to either our home page or the article URL.

At the bottom of the story, please include the following text:

“Modern Farmer is a nonprofit initiative dedicated to raising awareness and catalyzing action at the intersection of food, agriculture, and society. Read more at <link>Modern Farmer</link>.”

Use our widget

We’d like to be able to track our stories, so we ask that if you republish our content, you do so using our widget (located on the left hand side of the article). The HTML code has a built-in tracker that tells us the data and domain where the story was published, as well as view counts.

Check the image requirements

It’s your responsibility to confirm you're licensed to republish images in our articles. Some images, such as those from commercial providers, don't allow their images to be republished without permission or payment. Copyright terms are generally listed in the image caption and attribution. You are welcome to omit our images or substitute with your own. Charts and interactive graphics follow the same rules.

Don’t change too much. Or, ask us first.

Articles must be republished in their entirety. It’s okay to change references to time (“today” to “yesterday”) or location (“Iowa City, IA” to “here”). But please keep everything else the same.

If you feel strongly that a more material edit needs to be made, get in touch with us at [email protected]. We’re happy to discuss it with the original author, but we must have prior approval for changes before publication.

Special cases

Extracts. You may run the first few lines or paragraphs of the article and then say: “Read the full article at Modern Farmer” with a link back to the original article.

Quotes. You may quote authors provided you include a link back to the article URL.

Translations. These require writer approval. To inquire about translation of a Modern Farmer article, contact us at [email protected]

Signed consent / copyright release forms. These are not required, provided you are following these guidelines.

Print. Articles can be republished in print under these same rules, with the exception that you do not need to include the links.

Tag us

When sharing the story on social media, please tag us using the following: - Twitter (@ModFarm) - Facebook (@ModernFarmerMedia) - Instagram (@modfarm)

Use our content respectfully

Modern Farmer is a nonprofit and as such we share our content for free and in good faith in order to reach new audiences. Respectfully,

No selling ads against our stories. It’s okay to put our stories on pages with ads.

Don’t republish our material wholesale, or automatically; you need to select stories to be republished individually.

You have no rights to sell, license, syndicate, or otherwise represent yourself as the authorized owner of our material to any third parties. This means that you cannot actively publish or submit our work for syndication to third party platforms or apps like Apple News or Google News. We understand that publishers cannot fully control when certain third parties automatically summarize or crawl content from publishers’ own sites.

Keep in touch

We want to hear from you if you love Modern Farmer content, have a collaboration idea, or anything else to share. As a nonprofit outlet, we work in service of our community and are always open to comments, feedback, and ideas. Contact us at [email protected].by Max Leighton, Modern Farmer

January 8, 2015

Modern Farmer Weekly

Solutions Hub

Innovations, ideas and inspiration. Actionable solutions for a resilient food system.

ExploreExplore other topics

Share With Us

We want to hear from Modern Farmer readers who have thoughtful commentary, actionable solutions, or helpful ideas to share.

SubmitNecessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and are used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies.

Best cheese ever